The enzyme is an acid protease stable at pH 40-55 with a molecular weight of 34000 37500 daltons and is produced in a medium containing 3 soyameal 1 glucose 1 skim milk 03 NaNO 3 005 K 2 HPO 40025 MgSO 47H 2 O pH 68 at 25C incubation temperature. If it is desired the enzyme can be extracted.

Https Onlinelibrary Wiley Com Doi Pdf 10 1111 1541 4337 12326

SNO Macroscopic Analysis 1.

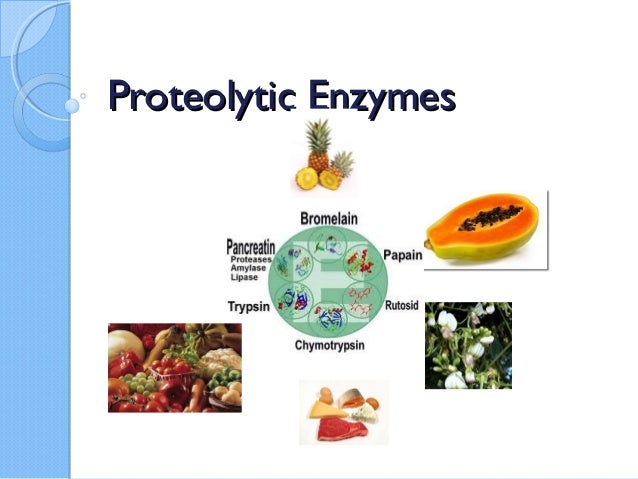

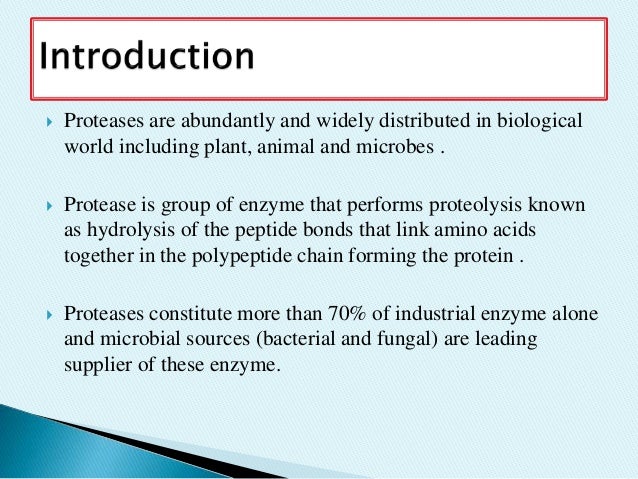

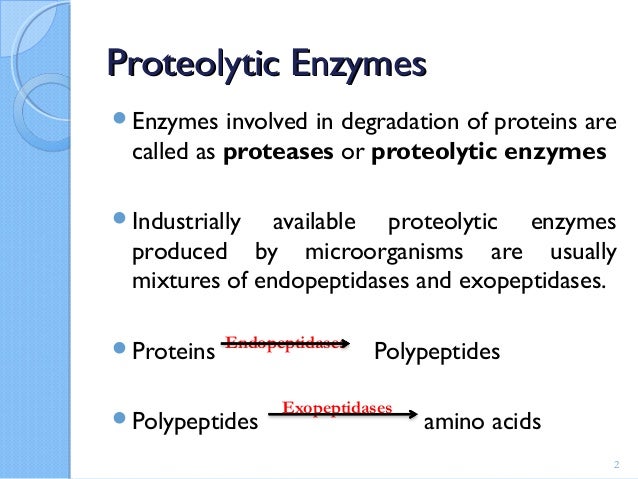

Protease enzyme production pdf. Proteases are a group of enzymes whose catalytic function is to hydrolyze peptide bonds of proteins and break them down into polypeptides or free amino acids. At the end of 48 hrs incubation period mycelium is separated and. Enzyme production Alkaline protease was produced in submerged fermentation which was carried out in 250 ml Erlenmeyer flasks containing 100 ml of liquid medium for enzyme production.

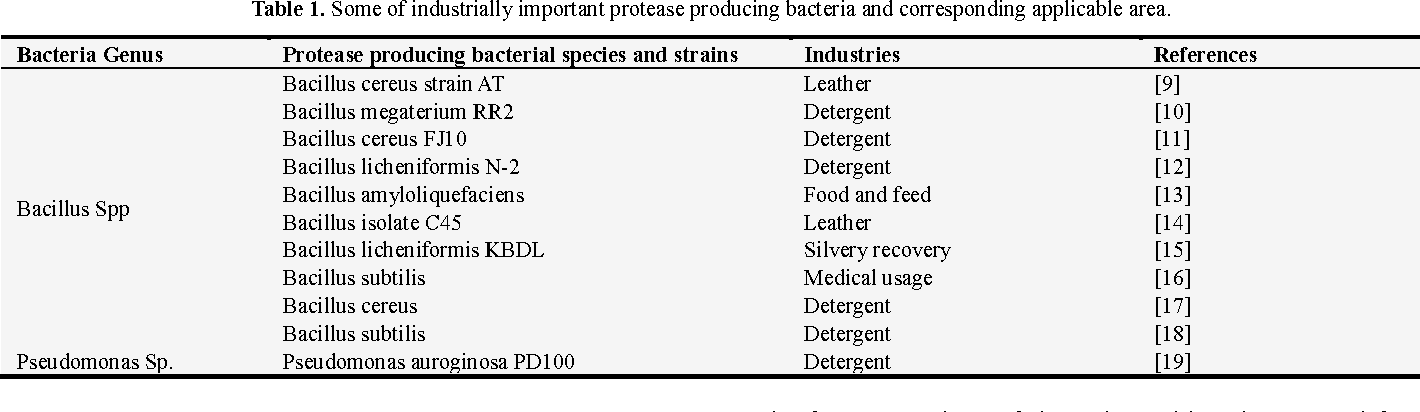

Besides this nutritional factor physical reaction mixture containing 20 ml of 05 per cent casein factors such as inoculum concentration3 temperature solution in 01 M CO. Of 56 bacterial strains tested as many as 60 to 83 of the strains produced at least one of the three enzymes and 47 of strains were able to produce all three enzymes. Alkaline proteases have various applications in industrial products and processes such as detergents food pharmaceuticals and leatherFor the alkaline protease production a number of microbial strains were screened using.

Production and partial purification of protease enzyme by Bacillus laterosporus was the aim of this study. Enzyme production has made the fermentation process of industrial enzymes economically feasible. Carbon and nitrogen can influence protease enzymeAssay for Protease.

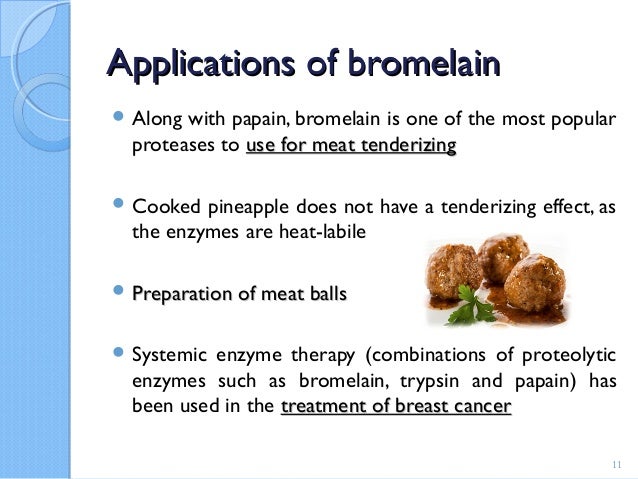

On the other end of the scale is the therapeutics. The aim of this study is to investigate the production of extracellular protease enzymes by Aspergillus niger using potato peel extracts as substrate and to optimize several fermentation parameters for optimum enzyme activity. CHAPTER 1 INTRODUCTION To produce environmental eco-friendly products and product out puts chemical process are being replaced by enzymes like proteases Abebe et al2014The technology for producing and using commercially important enzyme products combines the discipline of microbiologygeneticsbiochemistry and.

The optimum production is determined by withdrawing the growth from time to time and assaying for enzyme. Fig 1 Removal of blood stains by protease enzyme produced by Bacillus clausii SM3 at various intervals 1-10 min 2- 20 min 3- 30 min 4-40 min 5- 50 min. For production of enzyme 10 inoculums was added to 50 ml.

Inoculum preparation An isolated colony from the preserved culture plate was transferred into 50 ml Erlenmeyer flask Containing nutrient broth. The microbial protease was lacks pathogenicity. Laterosporus was allowed to grow in shake flask broth culture for purpose of inducing protease enzyme.

The protease enzyme was purified by ammonium sulfate precipitation followed by dialysis and further. Therefore they can be grow easily in culture medium and they have wide industrial applications 8. A temperature of 50C was found to be optimum for all the isolates for enzyme production.

Protease enzyme performs proteolysis which is catabolism of protein by hydrolysis of the peptide bonds. They constitute 59 of the global market of industrial enzymes which is expected to exceed 29 Billion by 2012 Deng et al2010. Protease enzymes can produce eco-friendly products and so they play a vital role in modern biotechnology industries 7.

Which are required in large volumes but have an inherently low unit value so that they demand significantly lower manufacturing costs. Activities of some commercial enzymes Some commercially-available enzymes that are used in Protease production media the early stages of leather manufacture were assayed Fungal cultures were grown on a medium containing for activity against several substrates including hide yeast extract 3 g L1 malt extract 3 g L1 both powder black Azocoll elastinCongo Red and ker- supplied by Oxoid. Identification Partial Purification and Characterization of Protease Enzyme from Locally Isolated Soil Bacterium By Md Ekhlas Uddin and Mohammad Khairul Islam Sarkar EXTRACTION AND PARTIAL CHARACTERIZATION OF PROTEASE PRODUCING BACTERIA THAT SHOWING SIGNIFICANT DEHAIRING CAPABILITIES.

Production and partial purification of protease enzyme by Bacillus laterosporus was the aim of this study. The industrial or bulk enzymes include proteases amylases lipases etc. Colour White Microscopic Analysis.

Yeast extract was found to be the optimum nitrogen source for protease enzyme production by all the test isolates. Protease enzymes are produced in. Protease production by alkaliphilic marine bacteria Bacillus cereus.

The production period is usually 30-40 hours but could be as long as seven days. Inoculums OD 660 nm were developed by growing the isolate in nutrient broth for 24 h. The protease enzyme was purified by ammonium sulfate precipitation followed by.

Colony Morphology Filamentous with filamentous margin 2. Amylase 00505 IUml carboxymethylcellulase 00505 IUml and protease 0105 IUml producing bacteria. Soy cake found to be the best substrate for enzyme production among.

The material is dried with hot air at about 37C40C and ground The enzyme is usually preserved in this manner. Bacillus laterosporus was allowed to grow in shake flask broth culture for purpose of inducing protease enzyme. The enzyme was assayed in the production.

Under submerged fermentation conditions a high level of protease production was found at 45 C after 36 h at pH 10 with continuous agitation 180 rpm. The presence of galactose and peptone in the medium enhanced enzyme production by 05 when. Production Of Protease Enzyme For enzyme production media consisting of Casein 20 Dextroses 10 Peptone - 10 KH 2 PO 4 - 20 NaCl 2 02 CaCl 2 0002 at P H 70 was used.

Enzyme production relied on the natural hosts as raw materials however genetic.

Microbial Proteases And Application As Laundry Detergent Additive Scialert Responsive Version

Pdf Bacterial Protease Enzyme Safe And Good Alternative For Industrial And Commercial Use Semantic Scholar

Protease An Overview Sciencedirect Topics

Https Onlinelibrary Wiley Com Doi Pdf 10 1111 1541 4337 12326

Process Flow Chart For Enzyme Production Download Scientific Diagram

Pdf Bacterial Protease Enzyme Safe And Good Alternative For Industrial And Commercial Use Semantic Scholar

Pdf Bacterial Protease Enzyme Safe And Good Alternative For Industrial And Commercial Use Semantic Scholar

Pdf Bacterial Protease Enzyme Safe And Good Alternative For Industrial And Commercial Use Semantic Scholar

Protease Enzyme Application In Food Processing

Pdf Bacterial Protease Enzyme Safe And Good Alternative For Industrial And Commercial Use Semantic Scholar

Pdf Bacterial Protease Enzyme Safe And Good Alternative For Industrial And Commercial Use Semantic Scholar

Https Onlinelibrary Wiley Com Doi Pdf 10 1111 1541 4337 12326

Protease Enzyme Application In Food Processing

Image Slidesharecdn Com Proteaseenzymes 1510060

Protease Enzyme Application In Food Processing

Protease Enzymes And The Benefits Beyond Cost Savings All About Feed